Today was our second trip of the summer, this time to the Rutger's University Coastal Ocean Observation Lab (or "R.U.COOL") with the UP Robotics FLL students and families along as well to see first hand the most advanced ocean observatory in the world AND arguably the world's most foremost underwater robotics program.

Our host for the day was Tina Haskins, a young lady who spent her high school days loving AP Biology class and being on the school's robotics team. Now in her mid twenties, she's a biological oceanographer and a robotic glider technician who just happens to be part of the first team EVER to "fly" an underwater robotic glider across the atlantic ocean - sampling the ocean along the way. That robot, "The Scarlet Knight" or "RU27" is now in the Smithsonian.

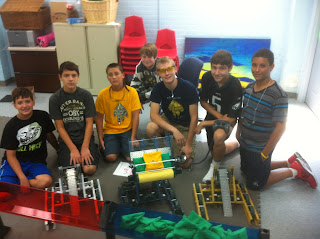

During our visit our students got to see the glider lab, the ocean observatory, the ballasting tank, met a bunch of awesome people, and got to learn nomenclature of the robotic gliders while assembling them.

In short, an INSPIRING day thanks to R.U. COOL!

More photos from the trip:

http://www.flickr.com/photos/uprobotics/sets/72157630860615500/

Video of student glider assembly:

http://www.youtube.com/watch?v=evjTKmbaWAs